During the aging process, the aluminum profiles undergo a controlled heating and cooling cycle that helps to stabilize and reinforce their internal structure. This is done by placing the profiles in a specialized aging furnace, where they are exposed to high temperatures over a set period of time. The exact temperature and duration of the aging process depend on the specific type of aluminum profile being produced, as well as the desired physical properties of the final product.

For profile aluminum square fold, the aging furnace must be carefully controlled to maintain a temperature between 190 and 220 degrees Celsius. This is essential for achieving the desired level of strength, hardness, and resistance to deformation, which are critical for ensuring the integrity and performance of the finished product.

To ensure optimal results, it is important that the temperature controller in the aging furnace is carefully calibrated and maintained. This involves regular checks and adjustments to ensure that the temperature remains consistent throughout the entire production process. Any fluctuations or deviations in the temperature can result in defects or inconsistencies in the finished product.

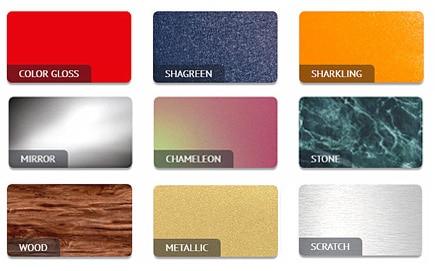

In addition to maintaining precise temperature control, it is also important to use high-quality materials and equipment throughout the production process. This includes using quality aluminum alloys, advanced machinery, and other specialized tools and technologies. For instance, the use of nano aluminum composite panels and pre-coated aluminum coils can help to enhance the durability, strength, and overall performance of the finished product.

As a leading supplier of aluminum composite panels and related products, including nano aluminum composite panels and wooden aluminum composite panels, we understand the importance of using the latest technologies and best practices in our manufacturing processes. We take great pride in producing high-quality products that meet the needs and expectations of our customers, while also contributing to a more sustainable and environmentally friendly future.

If you are looking for a trusted and experienced supplier of aluminum composite panels, look no further than our factory. With our state-of-the-art facilities, knowledgeable staff, and commitment to excellence, we are dedicated to providing our customers with the highest quality products and services in the industry. Contact us today to learn more about our products and services, and how we can help you achieve your specific goals and objectives.